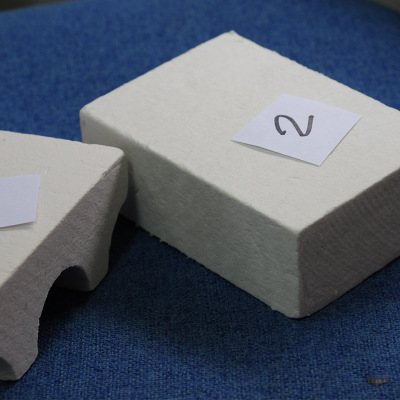

Vacuum formed ceramic fiber processed products

Product variety:Ordinary refractory (ceramic) fiber processed products

High purity refractory (ceramic) fiber processed products

High alumina refractory (ceramic) fiber processed products

Zirconium containing refractory (ceramic) fiber processed products

Product features:Can be made into various complex shapes with strong adaptability;

Soft and lightweight;

Having the same type of ceramic fiber in terms of fire resistance and thermal insulation performance;

Convenient construction and installation.

Application scope:Burner nozzle components for petrochemical fission furnaces;

Observation hole components in various industrial kilns;

Riser sleeve components used in the non-ferrous and black metallurgical industries;

Thermal pipeline insulation fittings;

Plugs, aluminum sinks, and immersion pipes used in the aluminum industry;

Various complex geometric shape kits used in thermal insulation engineering.

Refractory (ceramic) fiber vacuum formed processed products

Product Name、model project | Common | High purity type | High alumina type | Zirconium containing type |

STD | HP | HA | ZA |

Classification temperature (℃) | 1100 | 1260 | 1350 | 1400 |

Grading temperature(℃) | 1000 | 1100 | 1200 | 1350 |

Unit weight(Kg/m3)±15% | 200-400 | 200-400 | 200-400 | 200-400 |

Heating line contraction% [unit weight(200Kg/m3)] | 1100℃×24h ≤4 | 1260℃×24h ≤4 | 1350℃×24h ≤4 | 1400℃×24h ≤4 |

chemical composition(%) |

AL2O3 | 45 | 47 | 54 | 38 |

SiO2 | 53 | 52 | 45 | 45 |

ZrO2 | 一 | 一 | 一 | 2~18 |

Fe2O3 | ≤1.20 | ≤0.30 | ≤0.20 | ≤0.20 |

K2 O+Na2 O | ≤0.5 | ≤0.25 | ≤0.20 | ≤0.20 |

Product specifications(mm) | Can be produced and processed according to user drawing requirements |

Explanation: The above data is the average value of the product and should not be considered as a guarantee value. Product acceptance shall be carried out in accordance with national standards or signed contracts