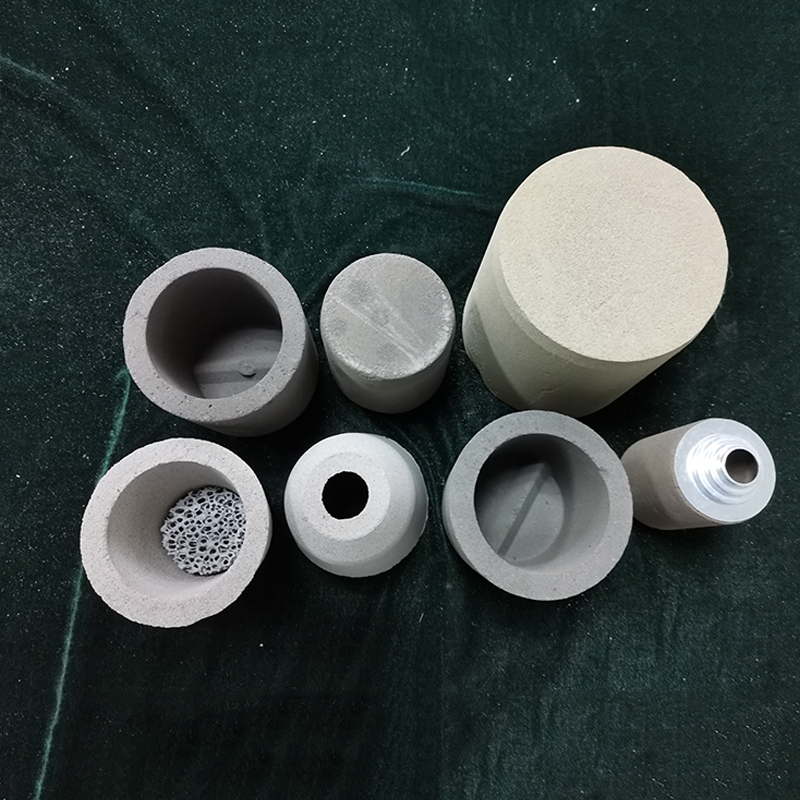

Professional supplier of ceramic fiber cloth, foam ceramic filter, fireproof cloth, high-precision industrial ceramics, casting ceramics and refractory materials

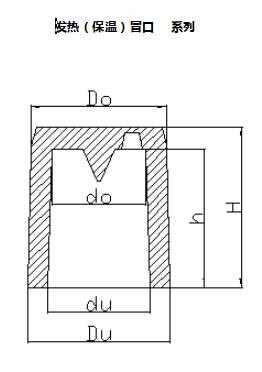

Specification and model | effective modulus | Geometric modulus | Dimensions of each part (mm) | Volume(cc) | |||||

Specif. | Eff.M | Geom. | du | Du | do | Do | h | H | Volume |

2/5 | 0.70 | 0.45 | 24.00 | 40.00 | 22.00 | 37.50 | 40.00 | 49.00 | 20 |

3.5/5 | 1.00 | 0.60 | 35.00 | 53.00 | 30.50 | 49.00 | 39.50 | 49.50 | 30 |

4/6 | 1.10 | 0.70 | 38.00 | 56.00 | 32.00 | 54.00 | 55.00 | 65.00 | 50 |

4/7 | 1.20 | 0.75 | 41.50 | 62.50 | 35.50 | 59.00 | 63.00 | 71.50 | 70 |

5/8 | 1.50 | 0.95 | 52.00 | 73.50 | 48.00 | 70.00 | 70.00 | 50.00 | 130 |

6/9 | 1.70 | 1.05 | 57.50 | 50.00 | 52.50 | 76.00 | 50.50 | 91.00 | 150 |

7/10 | 2.00 | 1.25 | 69.50 | 94.00 | 65.00 | 89.50 | 87.00 | 99.00 | 300 |

8/11 | 2.25 | 1.40 | 79.00 | 102.00 | 71.50 | 99.00 | 96.50 | 108.00 | 420 |

9/12 | 2.50 | 1.55 | 89.00 | 115.00 | 81.00 | 110.00 | 104.50 | 120.00 | 550 |

10/13 | 2.50 | 1.75 | 97.00 | 127.50 | 91.00 | 119.50 | 118.00 | 133.00 | 500 |

10/21.5 | 3.15 | 1.95 | 102.00 | 128.00 | 89.00 | 116.00 | 201.50 | 215.00 | 1400 |

12/15 | 3.20 | 2.00 | 118.00 | 154.50 | 112.00 | 148.00 | 130.00 | 150.00 | 1350 |

| Riser specifications | effective modulus cm | Geometric moduluscm | Volume cc | Do | do | H |

Specification | Effective Modulus | Geometric Modulus | Volume | mm | mm | mm | |

Straight barrel riser | 150x150 | 3.58 | 2.50 | 2649 | 195 | 150 | 150 |

180x180 | 4.29 | 3.00 | 4578 | 230 | 180 | 180 | |

200x200 | 4.77 | 3.33 | 6280 | 250 | 200 | 200 | |

225x225 | 5.36 | 3.75 | 8942 | 275 | 225 | 225 | |

250x250 | 6.04 | 4.17 | 12266 | 305 | 250 | 250 | |

275x275 | 6.65 | 4.58 | 16326 | 330 | 275 | 275 | |

300x300 | 7.25 | 5.00 | 21195 | 360 | 300 | 300 | |

325x163 | 5.90 | 4.07 | 13515 | 385 | 325 | 163 | |

| 7.85 | 5.42 | 26948 | 385 | 325 | 325 | |

350x175 | 6.13 | 4.38 | 16828 | 415 | 350 | 175 | |

| 8.17 | 5.83 | 33657 | 415 | 350 | 350 | |

375x188 | 6.57 | 4.69 | 20753 | 440 | 375 | 188 | |

| 8.75 | 6.25 | 41396 | 440 | 375 | 375 | |

400x200 | 7.00 | 5.00 | 25120 | 465 | 400 | 200 | |

| 9.33 | 6.67 | 50240 | 465 | 400 | 400 | |

450x150 | 6.21 | 4.50 | 23844 | 515 | 450 | 150 | |

| 8.87 | 6.43 | 47689 | 515 | 450 | 300 | |

| 10.35 | 7.50 | 71533 | 515 | 450 | 450 | |

500x167 | 6.71 | 5.01 | 32774 | 565 | 500 | 167 | |

| 9.58 | 7.15 | 65548 | 565 | 500 | 334 | |

| 11.17 | 8.33 | 98125 | 565 | 500 | 500 | |

550x184 | 7.28 | 5.51 | 43693 | 620 | 550 | 184 | |

| 10.39 | 7.87 | 87386 | 620 | 550 | 368 | |

| 12.10 | 9.17 | 130604 | 620 | 550 | 550 | |

600x200 | 7.80 | 6.00 | 56520 | 670 | 600 | 200 | |

| 11.14 | 8.57 | 113040 | 670 | 600 | 400 | |

| 13.00 | 10.00 | 169560 | 670 | 600 | 600 |

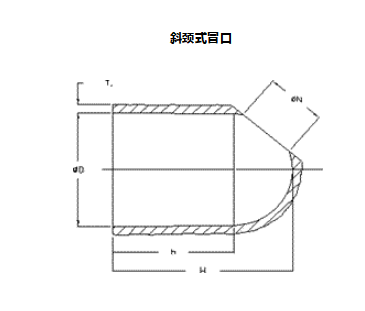

Riser specifications | effective modulus | Geometric modulus | Dimensions | Volume | |||||

Du | N | Do | do | H | h | Volume | |||

mm | mm | mm | mm | mm | mm | dm3 | |||

RND 80 | 1.99 | 1.37 | 70 | 39 | 100 | 78 | 100 | 27 | 0.42 |

RND 150 | 3.71 | 2.56 | 120 | 74 | 192 | 147 | 192 | 68 | 2.78 |

RND 180 | 4.33 | 2.98 | 132 | 88 | 222 | 175 | 222 | 90 | 4.44 |

RND 200 | 4.93 | 3.40 | 150 | 100 | 250 | 200 | 250 | 100 | 6.54 |

RND 225 | 5.54 | 3.82 | 160 | 113 | 278 | 225 | 278 | 110 | 9.32 |

RND 250 | 5.99 | 4.28 | 180 | 126 | 310 | 252 | 310 | 120 | 12.96 |

RND 300 | 7.08 | 5.06 | 210 | 150 | 360 | 300 | 360 | 140 | 21.31 |

RND 350 | 8.31 | 5.94 | 240 | 178 | 410 | 355 | 410 | 155 | 34.19 |

斜颈式冒口

| |||||||||

American | China | Geo.Mod(cm) | Eff.Mod(cm) | Volume(dm3 ) | Dimensions (mm) | |||||

Geo.Mod (cm) | Eff.Mod | Volume (dm3 ) | D | H | h | N | Tmin | Tmax | ||

7x3.5x12 | 180 | 3.46 | 4.67 | 6675 | 177.8 | 304.8 | 217.70 | 88.9 | 12.7 | 17.5 |

8x4x12 | 200 | 3.83 | 5.17 | 8588 | 203.2 | 304.8 | 204.70 | 101.6 | 12.7 | 17.5 |

9x4.5x12 | 225 | 4.15 | 5.60 | 10663 | 228.6 | 304.8 | 192.00 | 114.3 | 19.1 | 23.9 |

10x4x12 | 250 | 4.46 | 6.02 | 12787 | 254.0 | 304.8 | 224.50 | 101.6 | 19.1 | 23.9 |

12x4.8x12 | 300 | 5.04 | 6.80 | 18234 | 304.8 | 304.8 | 153.90 | 121.9 | 19.1 | 23.9 |

14x5.6x12 | 350 | 5.5 | 7.43 | 24002 | 355.6 | 304.8 | 128.50 | 142.2 | 19.1 | 23.9 |

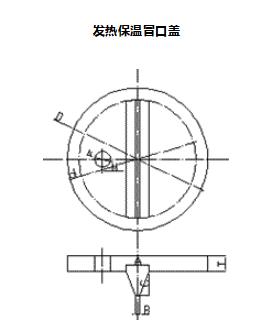

Heat insulation riser cover model | D | d | A | B | C | M | N | T | |

cap 150D | 180 | 150 | 30 | 5 | 30 | 30 | 20 | 20 | |

cap 180D | 230 | 180 | 30 | 5 | 30 | 37.5 | 22 | 25 | |

cap 200D | 250 | 200 | 30 | 5 | 30 | 42.5 | 24 | 25 | |

cap 225D | 275 | 225 | 30 | 5 | 30 | 48.8 | 26 | 25 | |

cap 250D | 305 | 250 | 30 | 5 | 30 | 55 | 28 | 25 | |

cap 275D | 330 | 275 | 35 | 5 | 35 | 60 | 30 | 30 | |

cap 300D | 360 | 300 | 35 | 5 | 35 | 66.3 | 32 | 30 | |

cap 325D | 385 | 325 | 40 | 5 | 40 | 71.3 | 34 | 35 | |

cap 350D | 415 | 350 | 40 | 5 | 40 | 77.5 | 36 | 35 | |

cap 375D | 440 | 375 | 40 | 5 | 40 | 83.8 | 38 | 35 | |

cap 400D | 465 | 400 | 40 | 5 | 40 | 90 | 40 | 35 | |

发热保温覆盖剂 | |||||||||

Riser diameter |

| Riser diameter |

|

60 | 0.04 | 350 | 2.00 |

80 | 0.07 | 400 | 2.80 |

100 | 0.12 | 450 | 3.90 |

125 | 0.18 | 500 | 5.10 |

150 | 0.28 | 600 | 7.50 |

175 | 0.35 | 700 | 11.00 |

200 | 0.50 | 800 | 16.00 |

250 | 0.95 | 900 | 20.00 |

300 | 1.30 | 1000 | 27.00 |