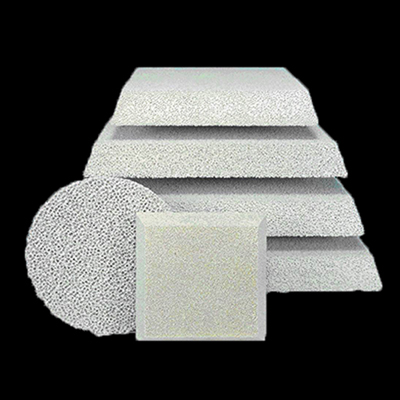

The structure and materials of ceramic foam filter.

The research on foam ceramic filters mainly focuses on three aspects: first, the materials of foam ceramic filters, including the manufacturing process and performance of foam ceramic filters; The second is the structure of the foam ceramic filter, including the shape, position, filtration mechanism, and filtration effect of the filter. The third is reuse.The selection of filter materials should be based on the type of debris to be removed during filtration, taking into account the material's resistance to creep and thermal vibration. A large number of experimental results indicate that the material, porosity, and inner surface roughness of foam ceramic filters can affect the filtration effect.

The structure of foam ceramic filters is determined by their materials, and foam ceramic filters can be divided into foam ceramic filters and granular foam ceramic filters.

Solution for clogging of foam ceramic filters.

Secondly, the foam ceramic filter is clogged.

The two possible factors for foam ceramic filters are rupture and blockage: rupture can lead to failure; Blocking the hole can lead to poor slag absorption effect of the filter plate, and even prevent it from flowing. If the foam ceramic filter is blocked, replace it with a new one in a timely manner.

The cleaning of foam ceramic filters is divided into two parts: backwash cleaning (also using gas) and combined cleaning. The purpose of cleaning is to discharge clogged particles from the foam ceramic filter. Backwashing cleaning can directly check the water pressure after the water filter has been filtered. Generally between 0.08 and 0.12 MPa. If it is less than 0.05MPa, the flushing effect is poor, and even there is no flushing effect, resulting in blockage and accumulation, ultimately leading to clogging and scrapping of foam ceramic filters. Replace the filter element in a timely manner to ensure that the water pressure before filtration can provide a stable backwash water pressure. Joint cleaning is the use of methods such as ultrasonic vibration and nitric acid dissolution to effectively remove blockages that cannot be removed by backwashing. Generally speaking, foam ceramic filters should be cleaned every 8 hours for 1 hour. If the old board or slag absorption effect is poor, cleaning can be strengthened appropriately (such as shortening the cleaning cycle, extending the cleaning time, increasing nitric acid consumption, etc.).