Professional supplier of ceramic fiber cloth, foam ceramic filter, fireproof cloth, high-precision industrial ceramics, casting ceramics and refractory materials

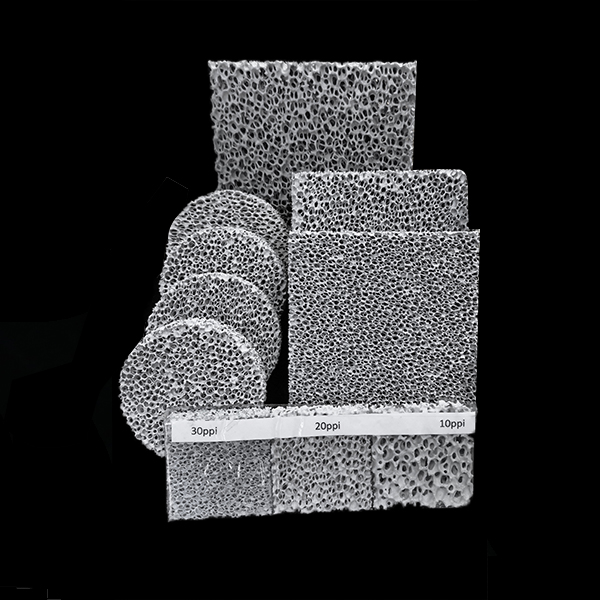

Silicon carbide foam ceramic filter

The basic material of the foam ceramic filter is silicon carbide. Silicon carbide has excellent strength and resistance to high temperature impact and chemical corrosion. It can withstand high temperatures up to about 1500°C. They are therefore suitable for casting all aluminium, copper and ductile gray irons.

Ceramic foam filters can significantly improve the quality of cast iron parts and reduce scrap rates, and can also be used in continuous casting and rolling processes and can be manufactured in all standard sizes and different thicknesses.

The foam ceramic filter has an excellent filtration effect on copper or molten iron, and uses a three-dimensional structure to effectively remove oxidation inclusions and other non-metallic inclusions by blocking capture adsorption. Whether it is gray iron, ductile iron, shaft body, cylinder block or complex large parts, precision hardware parts are filtered, the product quality will get very stable and satisfactory results.

Excellent raw materials and production technology ensure that the foam ceramic filter has stable dimensional tolerances. The foam ceramic filter produced by Suzhou Dexin Ceramic New Materials Co., Ltd. adopts raw materials imported from Germany and laser cutting process, which meets the requirements of manual modeling and higher efficiency mechanized production line, and ensures that the products of the foundry meet the requirements of international quality standards.

Foam ceramic filters are also adapted to copper and aluminum alloys to reduce turbulence and rectify the purified molten fluid. What is particularly valuable is that the life of the copper castings that have been filtered and purified is significantly extended in high-demand or harsh environments such as marine ship turbines and chemical parts, and it also has a good effect on copper castings with surface polishing requirements.

In the traditional copper industry, electrical and electronic copper industry, and continuous casting and rolling processes, foam ceramic filters also play an important role. Because copper and alloys, including zinc alloys, have a larger specific gravity and produce greater thermal shock during pouring, the use of silicon carbide foam ceramic filters in the copper casting process generally has strict specifications for size.

Reference data for partial silicon carbide foam filter flux: (round equivalence square)

Filtration volume sizemm | Ductile iron (≥kg) | Gray cast iron (copper alloy) (≥kg) |

40×40×11 | 15 | 30 |

50×50×22 | 30 | 60 |

75×50×22 | 75 | 150 |

100×50×22 | 110 | 220 |

75×75×22 | 110 | 240 |

100×100×22 | 200 | 390 |

150×150×25 | 400 | 780 |