Product parameter

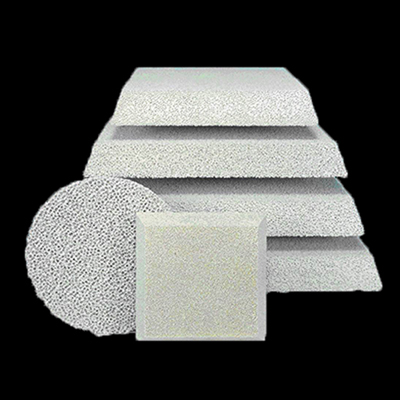

Alumina ceramic filter

Alumina foam ceramic filter, applicable temperature ≤ 1000°C, suitable for filtration and purification of aluminum and alloy solutions.

In order to meet the increasing quality requirements of aluminium castings, the use of alumina ceramic foam filters (plates) is becoming more and more important. Filters are also widely used in general sand casting such as tide mold casting and fixed mold casting such as automotive aluminum parts casting.

The use of the filtration process is mainly based on the following considerations: on the one hand, filtration makes the flow of molten aluminum orderly and relatively calm, and on the other hand, the solid slag in the molten metal is effectively removed, and the quality of the casting is rapidly improved.

Alumina foam ceramic filter products effectively remove solid inclusions in molten metal, so aluminum alloys can be smoothly forged, aluminum foil manufacturing, extrusion and other processes to obtain aluminum products. There are options ranging from 10 ppi coarse porosity to 40 ppi, so there will always be a product standard that suits your requirements. Both the common size and the special size required by the customer can meet the requirements.

Throughput reference data (20PPI) (square vs. round)

Specification(mm) | Filter the flow of molten aluminum(kg/sec) | The total weight of molten aluminum can be filtered(kg) |

Ф40×15 | 3.3 | 25 |

Ф55×15 | 4.8 | 40 |

Ф65×15 | 6.4 | 60 |

Ф75×22 | 8.1 | 100 |

Ф80×22 | 9.3 | 120 |

Ф95×15 | 11 | 200 |

Ф100×22 | 16 | 800 |

Note: If there is a circle, there is a corresponding square product |