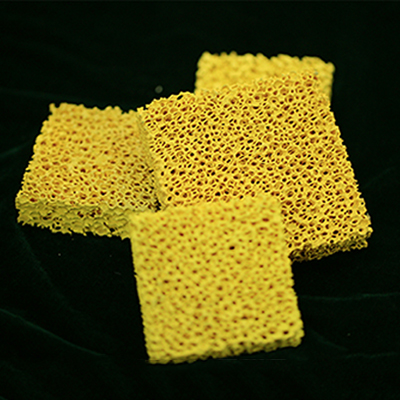

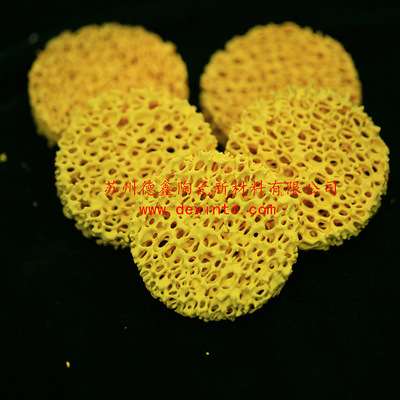

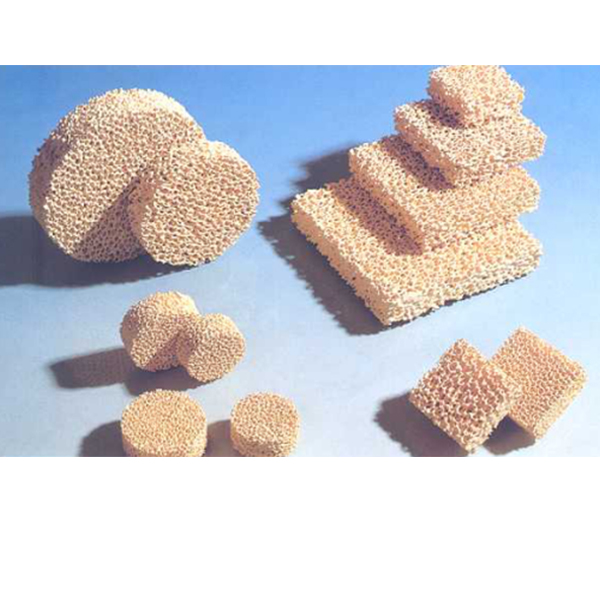

Zirconia foam ceramic filter

The basic material of the zirconia foam ceramic filter is zirconia ZrO2. The zirconia filter has a heat-resistant temperature of about 1700°C, which has very high strength and resistance to high-temperature impact.

Cast steel parts are widely used in areas that require high strength and elongation requirements. Therefore, steel castings are very sensitive to defects caused by impurities. The excellent characteristics of zirconia foam ceramic filter can effectively remove impurities that ultimately lead to product quality defects, which are mainly composed of non-metallic particles, slag, and refractory fragments, improve the surface quality and mechanical properties of castings, and reduce the scrap rate.

The zirconia foam filter can make the molten steel fill the cavity more evenly, and the molten metal has a higher turbulence tendency during pouring, and the turbulence through the three-dimensional pore structure of the foam ceramic filter is finally converted into a stable laminar flow. Laminar flow fills the cavity better, which reduces the impact corrosion of the metal solution on the casting cavity and significantly reduces the scrap rate.

Significant filtration effect on all steel grades, including carbon steel, stainless steel, cobalt-based nickel-based superalloys, etc.

Made of zirconia material, it is not sensitive to the change of pouring temperature of different steel grades.

Excellent raw materials and new production technology can make the filter screen have stable dimensional tolerance.

Non-metallic inclusions in castings are the most important cause of casting defects, affecting the surface finish, mechanical and machinability of castings and leading to higher scrap rates. Ceramic foam filtration products are designed to remove inclusions and reduce turbulence to achieve a fast and stable flow rate of molten metal and thus improve the quality of castings.

Suzhou Dexin Ceramic New Materials Co., Ltd. zirconia foam ceramic filter features:

* Significant filtration of all steel grades, including carbon steel, stainless steel, cobalt-based nickel-based superalloys, etc.

*Made of zirconia material, it is not sensitive to the change of pouring temperature of different steel grades.

* Excellent raw materials and new production technology can make the filter screen have stable dimensional tolerances, and at the same time meet the requirements of manual molding and more efficient mechanized production lines, and ensure that the product quality of the foundry meets the requirements of international quality standards.

Reference data for flux (10PPI)

Size(mm) | Maximum filter weight(kg) |

50×50×25 | 30 |

75×75×25 | 60 |

80x80x25 | 80 |

100×100×25 | 150 |

100×100×30 | 200 |

Ф50×15 | 20 |

Ф60×15 | 25 |

Ф90×25 | 80 |

Commonly used specifications and sizes(mm):

Ф50*15、Ф50*25 、Ф60*15、Ф60*25、Ф70*25、Ф80*25、Ф90*25、Ф100*25、Ф100*30etc. (the above are round, and the corresponding ones are square, and special-shaped parts can also be made by opening molds)

Commonly used porosity10ppi, 20ppi,30ppi